Coextrusion Film with Foamed Layers

High Output Line for Expanded Polystyrene Sheet

Description

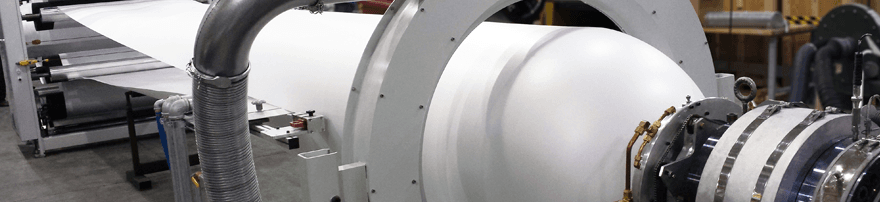

Macro’s PS Foam Extrusion Line is a tandem extruder system that produces expanded polystyrene sheet (EPS) at extrusion output rates up to 700 kg/h.

The key feature of the line is a newly designed innovative cooling screw that guarantees efficient cooling of the melt and highly uniform melt temperature distribution in the secondary extruder. This not only allows extrusion to occur at elevated outputs but also creates advantageous properties within the foam structure, such as an increased proportion of closed-cells, improving the overall strength of the foamed sheet.

The die is designed so die lip adjustments can be performed without shutting down the line, saving costs on materials and labour.

The line is equipped with a loss-in-weight feeding system that regulates an accurate blending ratio. The gas injection system can work with a range of physical blowing agents, and more than one agent can be injected simultaneously, if needed.

Along with the line, Macro provides the know-how to operate it; Macro supplies the complete recipe along with process training, and stands behind the machinery with industry-leading after sales support.

As with all Macro machinery, the line is constructed using the latest technology, highest quality materials and superior workmanship.

Key Features

- Extrusion output ~ 700 kg/h

- Innovative cooling screw guarantees uniform melt temperature distribution

- CO2 can be blended with butane

- Thickness range of 1.2 mm - 5.0 mm

Applications

- Food Packaging

- Meat trays

- Fruit & vegetable trays

- Egg cartons

- Clamshell packaging

- Plates, cups, bowls